About Me

Engineer.Innovator.Thinker

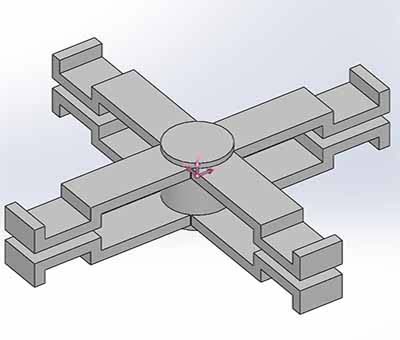

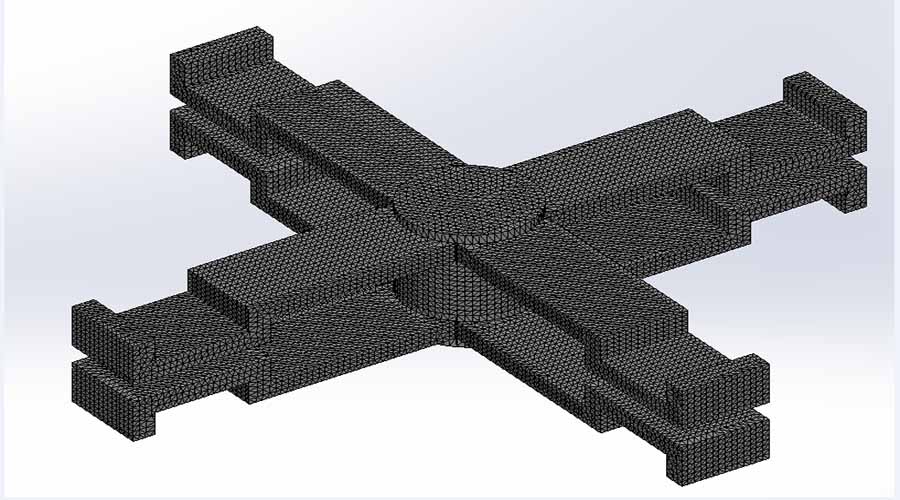

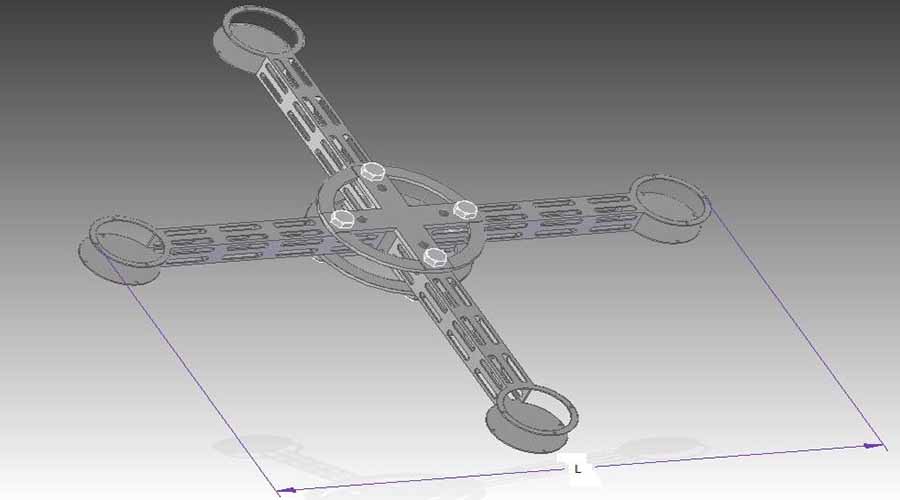

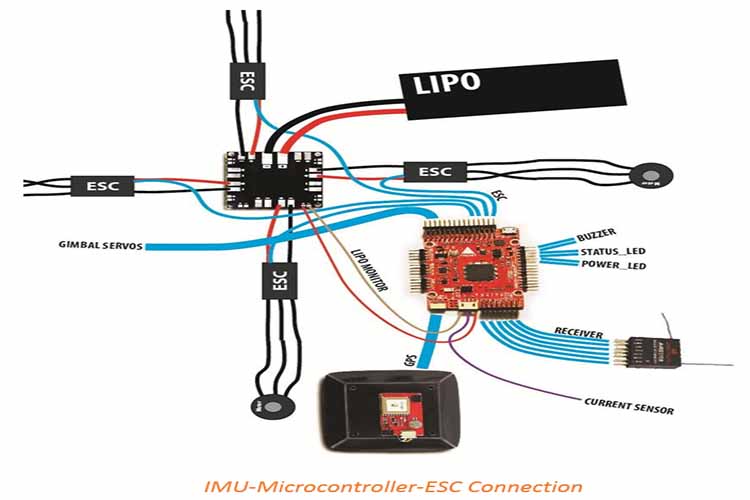

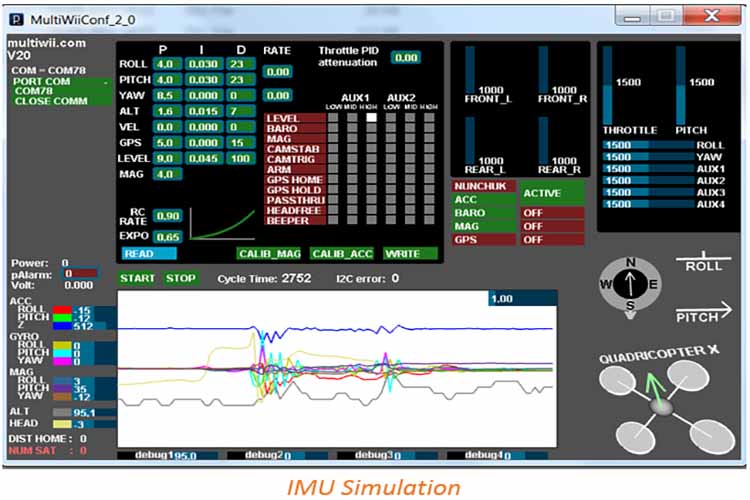

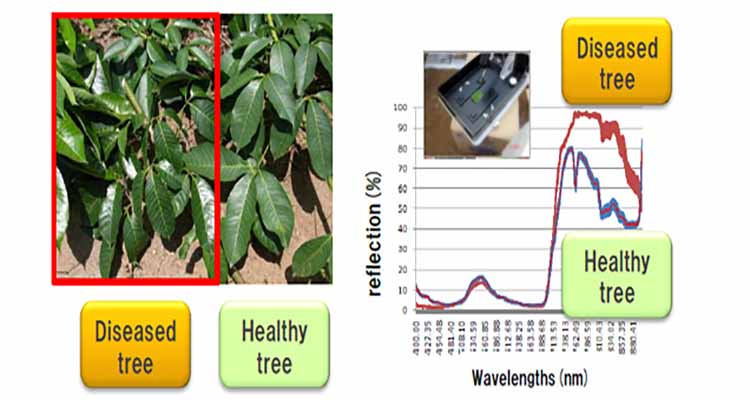

Product Design

Creating products and systems that optimizes function, value and appearance for the mutual benefit of both user and manufacturer.

My Mantra

"Innovation is a part of evolution, thus one must innovate to evolve in order to thrive in this dynamic ever changing world."

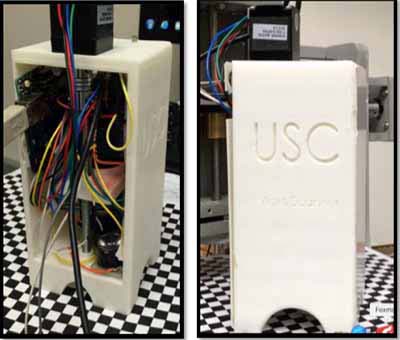

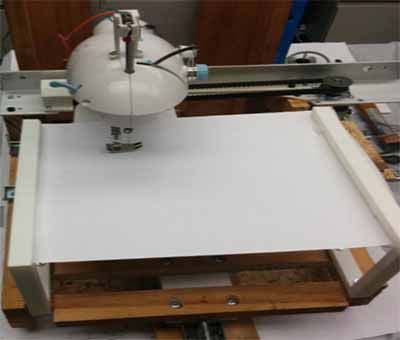

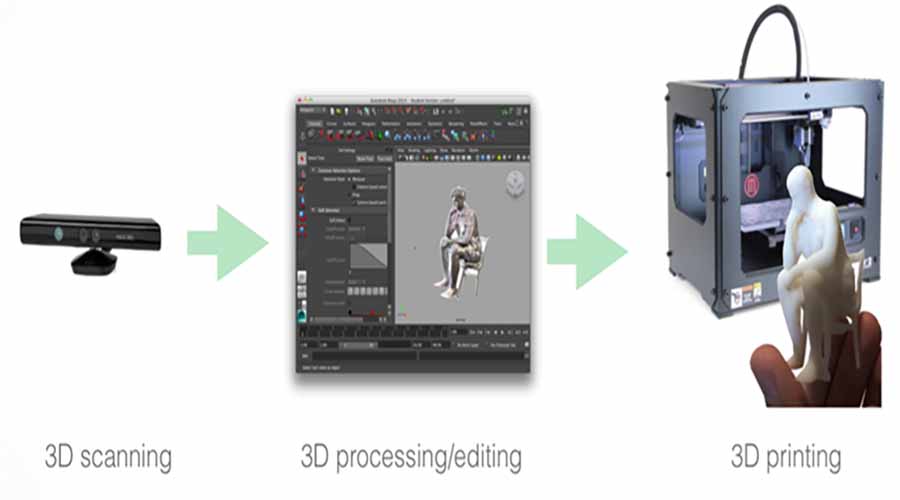

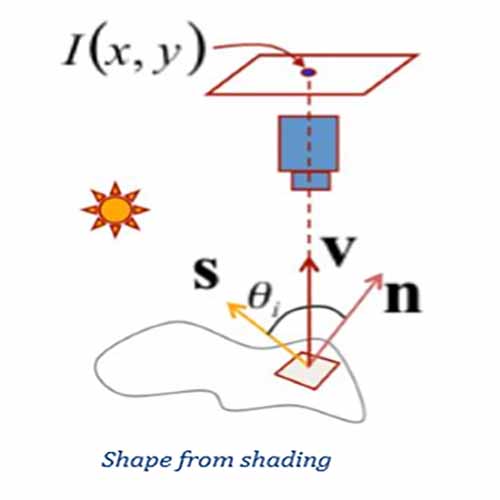

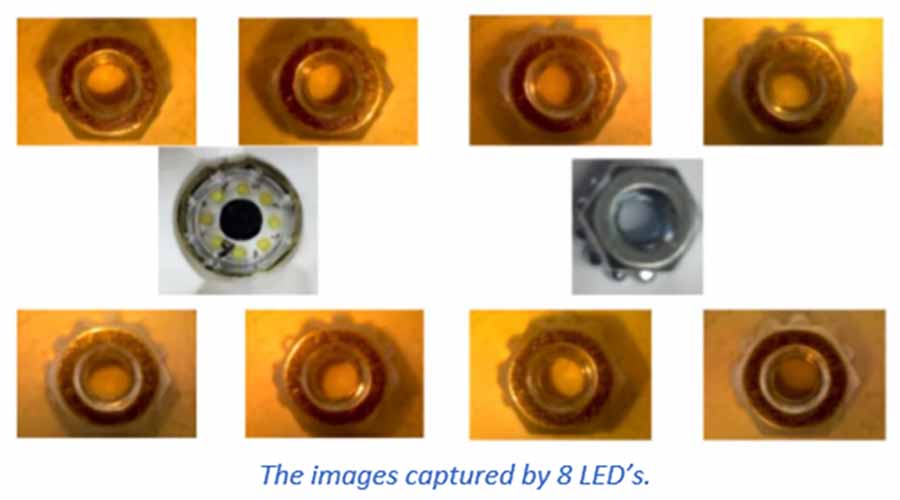

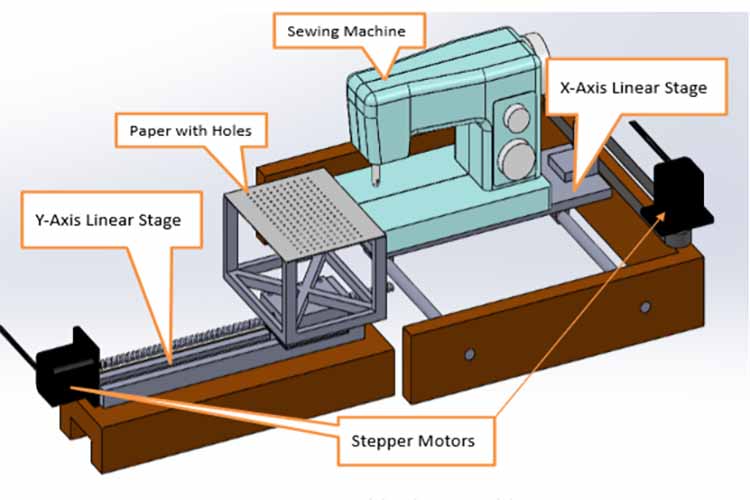

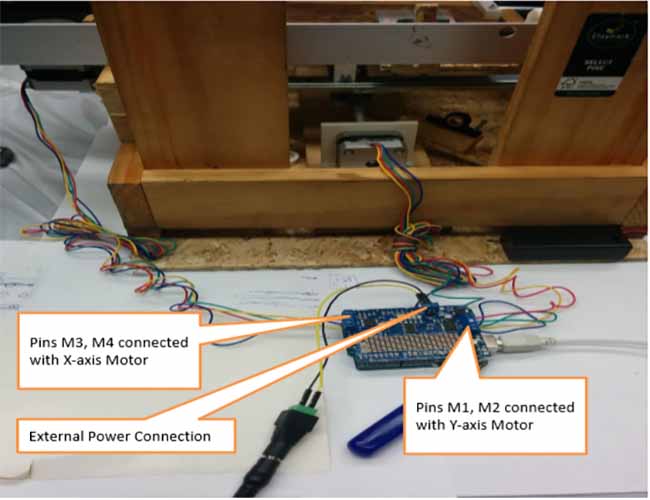

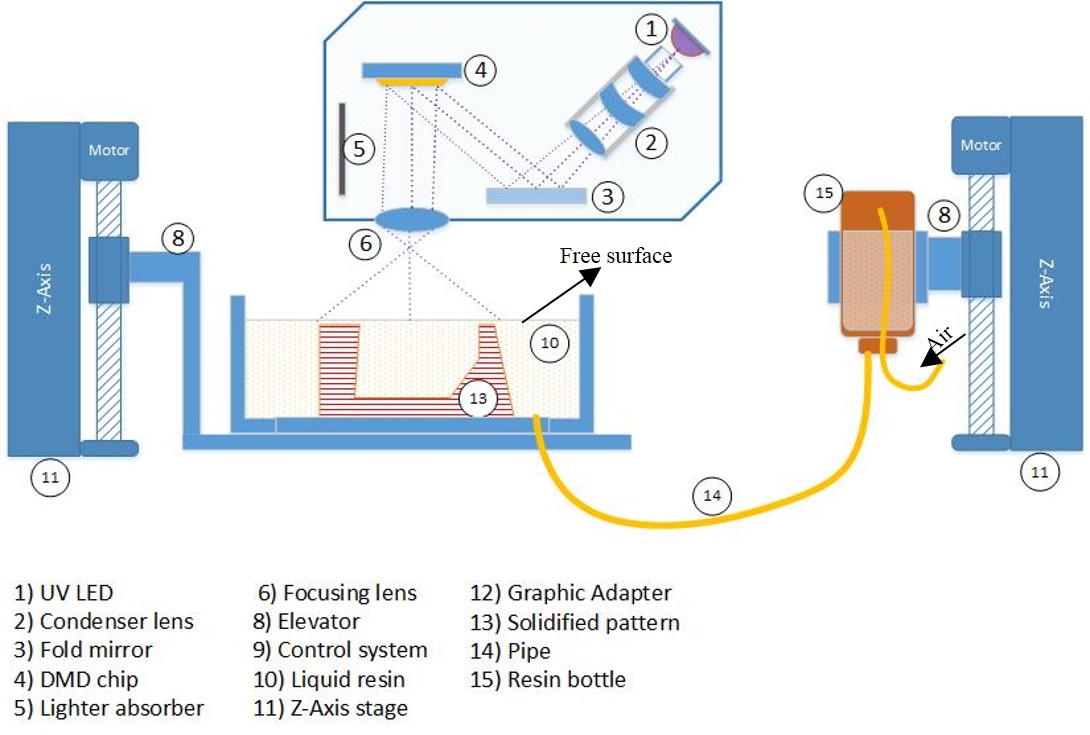

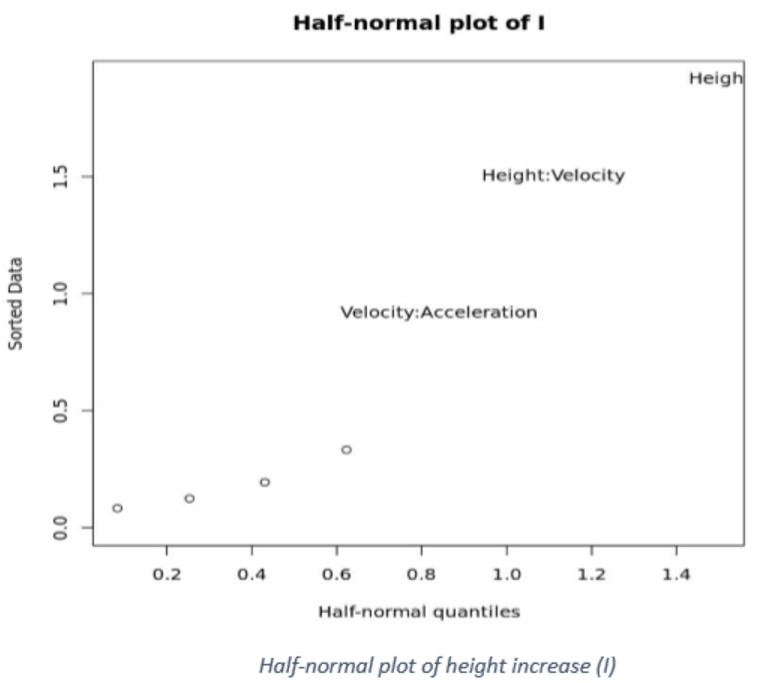

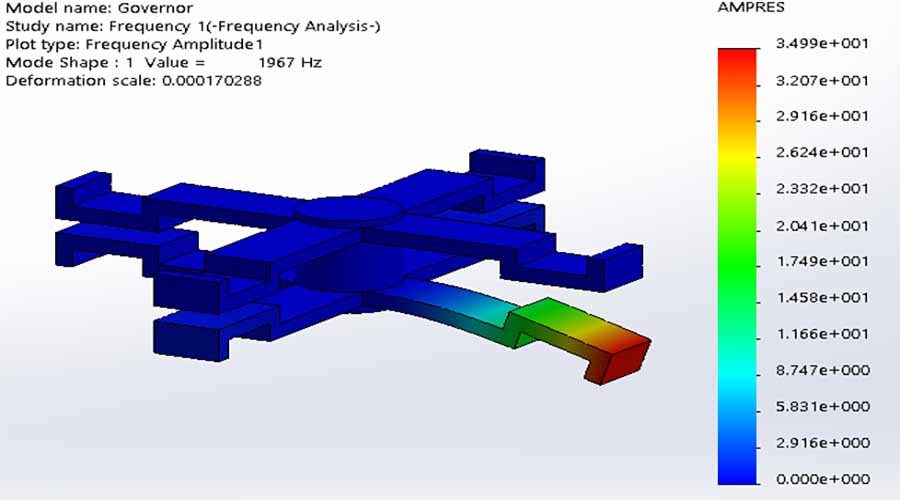

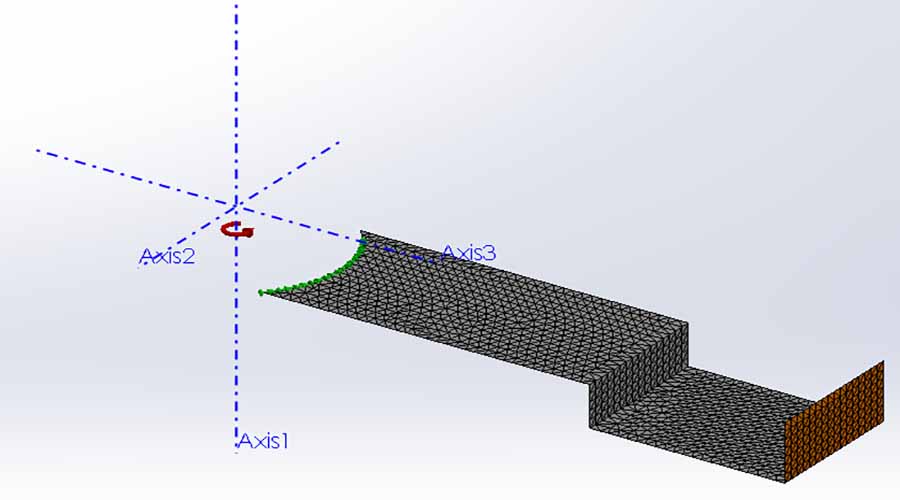

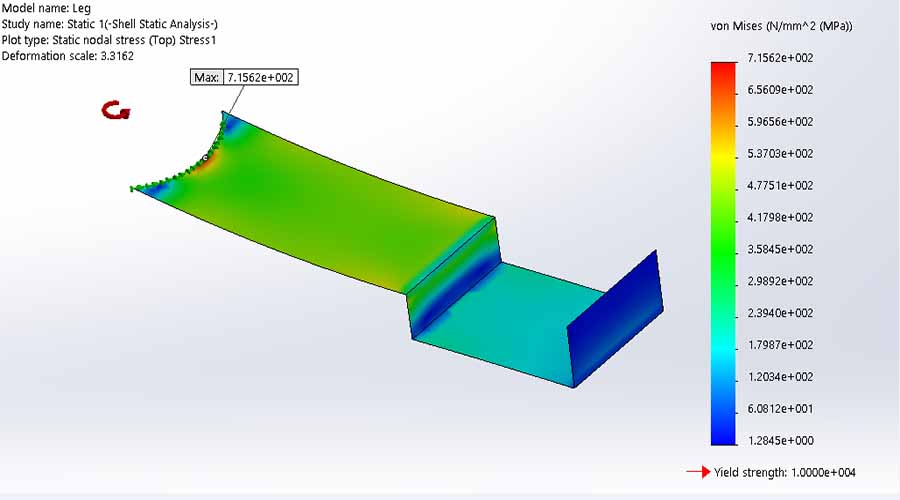

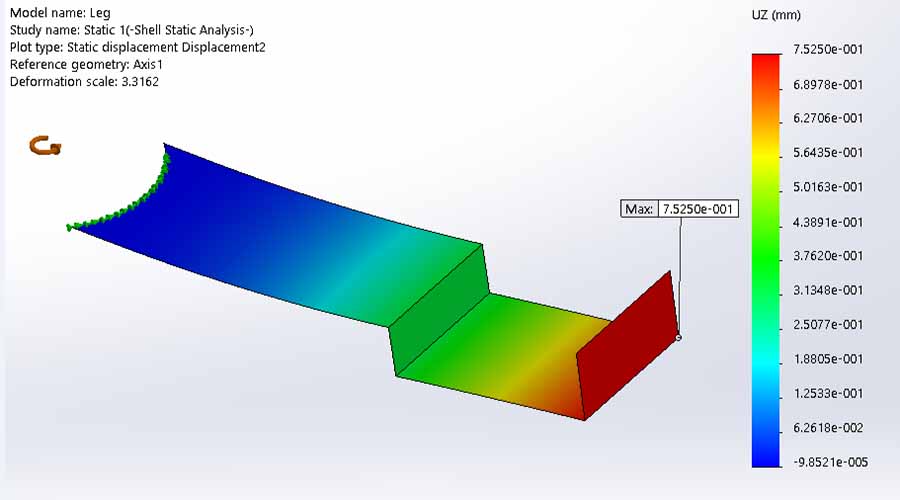

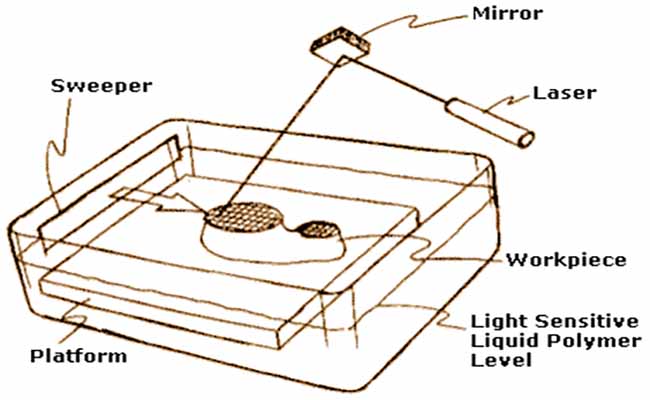

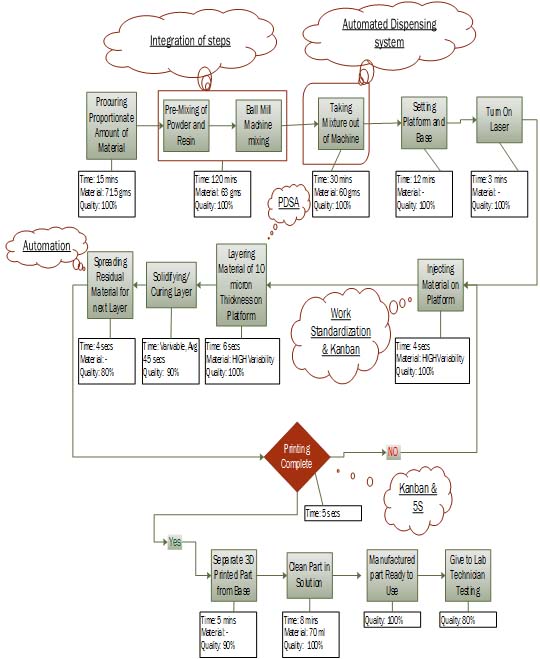

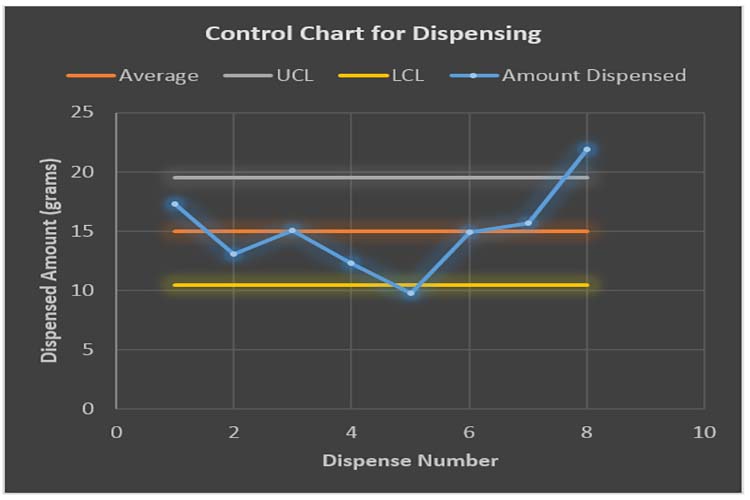

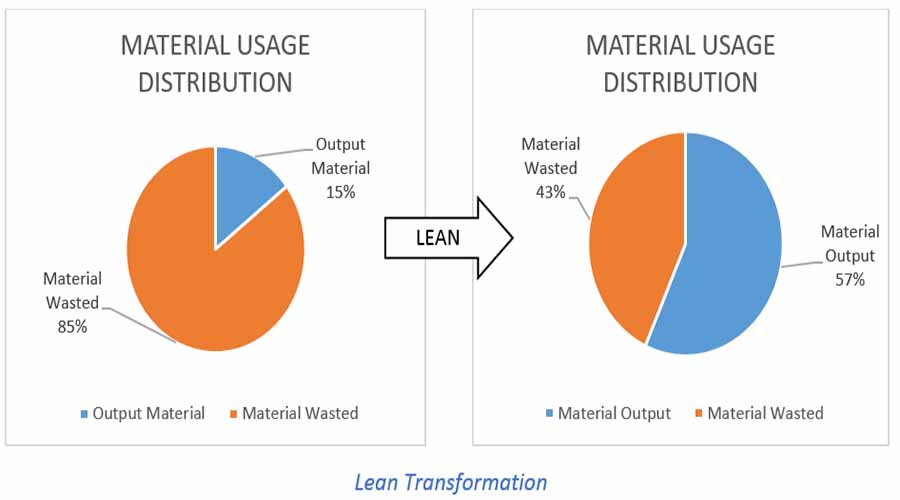

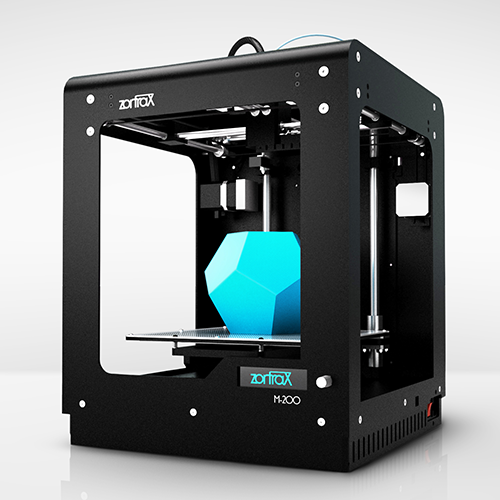

Manufacturing

Working on advanced manufacturing technologies like rapid prototyping, CAD/CAM/CAE and automated material handling systems like automated guided vehicles (AGVs).